Success Story on the use of EO to improve operational flows and planning

Shale development introduces a new level of operational complexity with respect to field operations for oil and gas operators. Long lead times reduce flexibility in operations. Delays in executing on the ground negatively impact the drilling schedule and cost operators real money. Overcoming technical challenges in shale operations by using high resolution spatial imagery and elevation models in operational workflows and planning for well pad locations and pipeline routing increases operational efficiency and production, while reducing operating costs and environmental impact. The results are striking – especially for operators who are running large scale drilling programs. The project looked at the operations from a typical large scale unconventional play.

The use of high resolution imagery and elevation data can provide a strong return when effectively used in the planning phase of field operations.

Summary of Benefits of Leveraging Imagery and dems in shale plays

Figure: Operational Complexity of shale development. © SpatialEnergy |

|---|

Since complexity of field operations seems to be an industry wide issue, Spatial Energy engaged with the client to document where the use of up-to-date high resolution imagery and DEMs would have a significant impact on their field operations. Together, we dug deep into their operational processes and were able to create a generalized workflow for locating a well pad and routing a new pipeline. We then worked with them to understand the kind of costs involved with these activities and to identify where in the workflow imagery and DEMs would provide a benefit. Together, we then calculated and verified the cost savings that could be captured. Once the usability and return on investment in acquiring the geospatial data was established, Spatial Energy provided a combination of high resolution aerial imagery and digital elevation models to reduce costs and increase efficiency in surface operations in the shale play area of the customer in the United States.

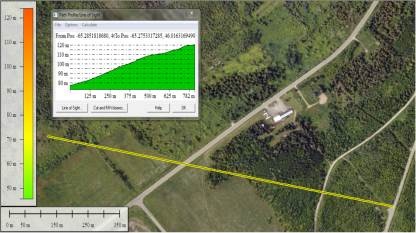

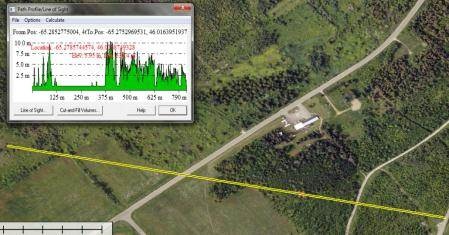

3D path profile using elevation model & imagery Images © SpatialEnergy | 3D path profile. Canopy height using digital elevation model & imagery |

|---|

Shale development introduces a new level of operational complexity with respect to field operations for oil and gas operators. Long lead times reduce flexibility in operations. Delays in executing on the ground negatively impact the drilling schedule and cost operators real money.

Specific operational objectives are:

Reduction of timeline in planning to SPUD/construction

Cost reduction in design and construction

Improved efficiency of personnel

The client used Spatial Energy to acquire eight hundred square kilometers of high resolution, 30cmAerial imagery and Intermap NEXTMap Digital Elevation Model bundled data (digital surface models and digital terrain models at 5m posting resolution, 1m vertical resolution, 2m absolute accuracy) in for their areas of interest in a Shale play in the United States. In addition, Spatial Energy trained the users on accessing and applying the datasets within existing or potential operational work flows to determine impact on operational cost and efficiency.

The overall objective was to use a combination of high resolution aerial imagery and digital elevation models to reduce costs and increase efficiency in surface operations. In addition, the geospatial data we provided was used to improve production in lateral wells due to increased accuracy in leasehold and well placements (xyz).

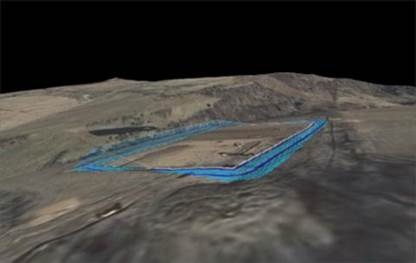

| (left) Aerial image (right) Pad site cut.fill with DEM © SpatialEnergy |

|---|

We were able to improve some of the technical challenges in the shale operations for this client by using high resolution Imagery and Elevation Models in operational workflows and planning for well pad locations and pipeline routing to increase the operational efficiency and production, while reducing operating costs and environmental impact.

Operational Cost Savings

Savings calculated for 300 wells planned in following year

The hard cost savings noted above were operational in nature. However, both Spatial Energy and the operators acknowledge that there are other costs savings that can be recognized, such as saving employee time, eliminating idle rigs and reduction of surface damages paid, among others. None of this was included in the project. |

|---|

DRILLING BENEFITS

- Ensure drilling has all information necessary to pick preliminary locations from the office, making the decision faster and making better use of drilling and field personnel time

- Reduce the number and duration of trips to the field and current success rate of 30-50% for determining useable locations on the ground should increase to near 100%

- More quickly estimate surface damages from the desk

- Stay further ahead of the drill schedule avoiding potential for idle rigs

- Accurately estimate time and cost to construct surface locations based on topography, vegetation, and surrounding infrastructure.

- Prioritize the drilling schedule and gain flexibility with better planning.

- Provides a baseline for contractor cost comparison and auditing.

- Significantly reduce time from planned well to approval for construction

FACILITIES BENEFITS

- Reduce field visits to determine location of existing infrastructure

- Determine preliminary/pre-stake routes faster, with more confidence, and higher success rate from the desktop

- Determine timing and level of effort to construct facilities ahead of wells and other activities (land, damages, contractor bidding, etc.)

- Quickly estimate potential surface damages from the desktop

- Avoid undesirable post-construction surface damages negotiation by staying further ahead of schedule and increased flexibility gained with a faster decision and planning process

Other uses of IMAGERY AND DEMs IN UNCONVENTIONAL DEVELOPMENT Energy companies can utilize imagery and DEMs across the enterprise and throughout the E&P process in both conventional and unconventional areas of operation. These uses include:

|

|---|

Source Spatial Energy

This page has no comments.