Oil rigs monitoringOffshore oil rigs are exposed to a number of dangerous situations, both because of their location and as a consequence of the nature of their operations. Risks are both for those who work on the platform and for the surrounding environment. It is thus crucial to put reliable control systems in place and monitor a number of parameters in order to guarantee the safety of people and ecosystems. Back in 2009 a Remote Intuitive Visual Operations System (RIVOPS) has been developed by a French-Dutch start-up called EATOPS, in the context of an ESA incubation programme. It consists of an alarm monitoring system based on satellite monitoring to be add on top of conventional control systems traditionally used by offshore oil and gas exploration companies. The combination of thousands of monitored parameters into clusters and algorithms leads to a graphical and intuitive overview of emergency situations that can occur in offshore structures. The outcome is a quicker and more efficient identification of critical situations and problems. Satellite control and Earth monitoring provide expertise in organising parameters and using intuitive visualisation techniques as a safe tool for fast decision-making in environmental and disaster management domains. |

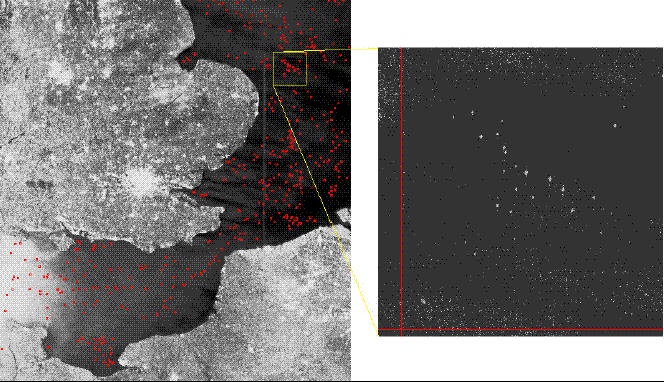

Radarsat ScanSAR image of the English Channel and North Sea showing ship/oil rig detections. Credits: Space Dept. DERA, UK. Data copyright: Canadian Space Agency |

|

This proved very useful when applying similar schemes to offshore platforms, letting few operators understand possible issues and take quick decisions to address and solve the problems: this sharp understanding of emergencies increases the overall safety on the rigs and also decreases environmental risks (1). Gas flares

BP Ula oil platform in the North Sea. Credits: Daniele Pugliesi |

During oil extraction and processing offshore, raw natural gas can be released to the surface as a byproduct. Flaring is a gas combustion device used for burning off flammable gas when it is not economically or technically storable and transportable. The practice can be used both to protect plant equipment against the dangers of gas release, to respond to emergencies or just to dispose of unusable gas in areas where pipelines and transportation infrastructrure are missing. The effects of flaring on the environment are still a research topic, but there is agreement on its potential harmfulness and some studies suggested that climatic and atmospheric conditions may influence the effects of gas-flaring heat and chemical emissions (2). NASA's Visible Infrared Imaging Radiometer Suite has been used to assist in monitoring and managing gas-flaring: aerosol levels and other trace gas pollutants can be examined to better understand the phenomenon, Atmospheric Infrared Sounder data are inputs to determine relative humidity levels, and Ozone Monitoring Instrument data provides measurement of nitrogen dioxide (NO2) and sulfur dioxide (SO2). Other remote sensing intruments provide data to determine CO2 levels. All these information are useful for the industrial plants themselves, for public authorities monitoring atmospheric pollution, and for communities at large, to have reliable scientific data on the status of the environment. |

|

References (1) ESA, technology transfer programme, DOWN TO EARTH: how space technology improves our lives. (2) To Flare or not to Flare: Satellite Assessment of Gas Flaring and Climate Relationships, Earthzine 2013 |